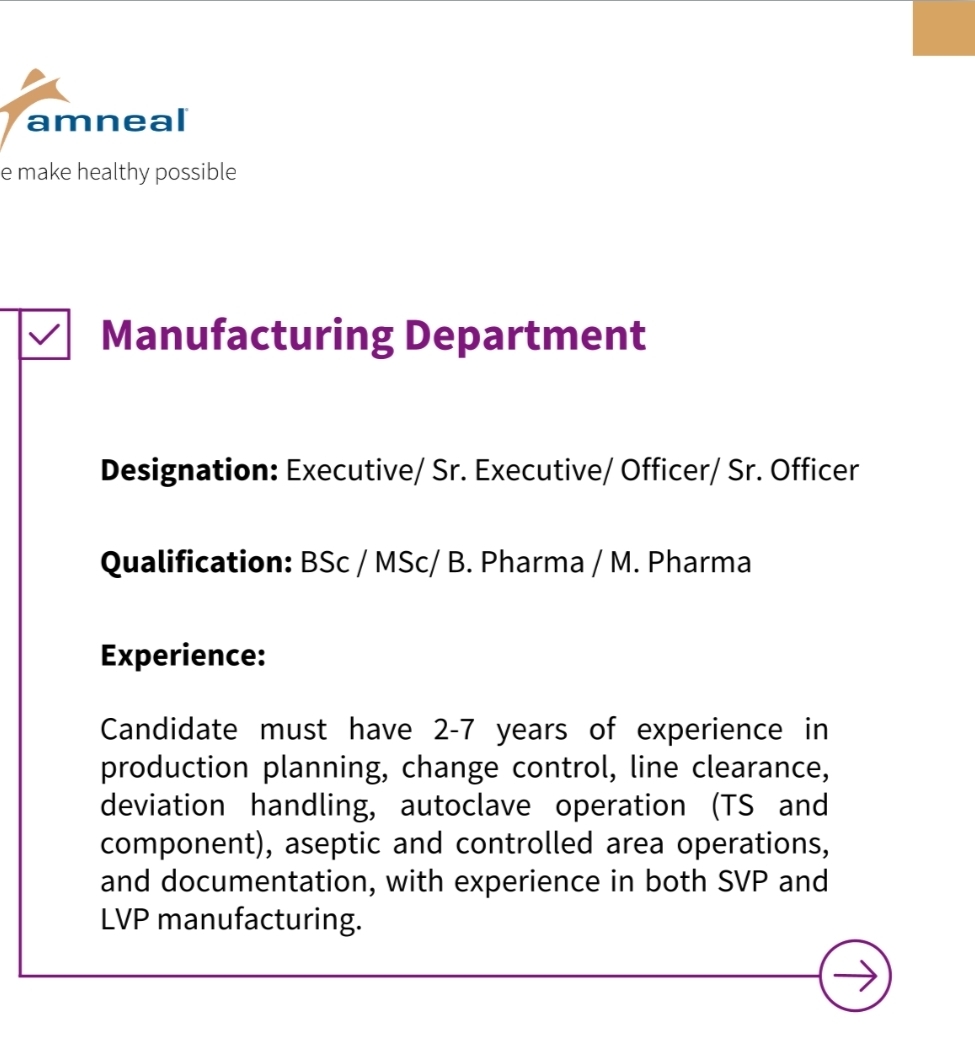

💼 Amneal Pharmaceuticals Hiring for Injectable Manufacturing Roles – Walk-in Interview on 13th July 2025!

📍 Location: Pipan, Sanand, Ahmedabad, Gujarat

📅 Date: Sunday, 13th July 2025

🕘 Time: 9:00 AM to 2:00 PM

🏢 Venue: Amneal Pharmaceuticals Pvt. Ltd., Plot No: 161/1, Sanand Bavla Highway Road, Village: Pipan, Sanand, Ahmedabad – 382110

🔍 About the Company

Amneal Pharmaceuticals, Inc. (NYSE: AMRX) is a leading global pharmaceutical company with a robust portfolio of 270+ high-quality medicines. With over 7,500+ employees, Amneal is committed to making healthier lives possible through innovation, development, and world-class manufacturing.

👨🔬 Current Openings at Injectable Regulated Plant

Department: Manufacturing (Production & Packing)

Job Roles:

-

Operators

-

Officers

-

Executives

Location: Pipan, Sanand – Ahmedabad

Experience Required: 2 to 7 Years

Qualifications: ITI / Diploma / B.Sc / B.Pharm / M.Sc / M.Pharm / B.E

✅ Required Skills & Hands-On Experience In:

-

Sterile / Parenteral / Aseptic processing

-

Filling, Sealing, Filtration, and Production QMS

-

Batch Manufacturing

-

Autoclave operations

-

Terminal Sterilization

-

Packing & Visual Inspection

Lines Handled: Ophthalmic, Vial, PFS, LYO, Cartridges, Bag, Inhalation

🛠️ Machine Exposure (Preferred):

-

Filling machine (Groninger / Optima)

-

Dyno Trucking

-

Bosch Filling Machine

-

Steam Sterilizer (Fedegre)

📧 How to Apply:

If you're unable to attend the walk-in, send your updated CV with the subject line

“Application for INJ Manufacturing/ Packing” to:

📩 ajaykumar.pandey@amneal.com

📩 Hitenkumar.Patel@amneal.com

Or Scan the QR Code on the image to apply online.